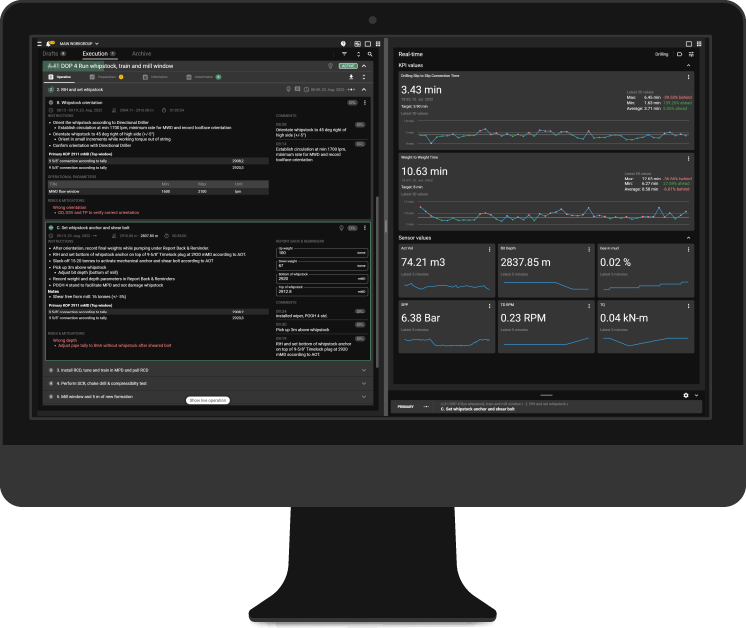

It’s not about the amount of data you collect, but the ability to see which data has the most value at any given time

Our experts come from the industry and have extensive experience in identifying the information that provides the greatest value for optimal work processes. Together with our users, we also receive suggestions for new and great improvements.

Closing the Gap between planning and execution

Work instructions for well operations are still based on paper. This paper based process for creating, approving and distributing work instructions is inefficient.

A lack of visibility of operational status leads to excessive communication, and limited operational transparency. Progress is typically recorded manually on 24h basis, and provides poor data for operations.

H56 solves this problem by digitalising these operations information workflows and closing the gap between planning and execution.

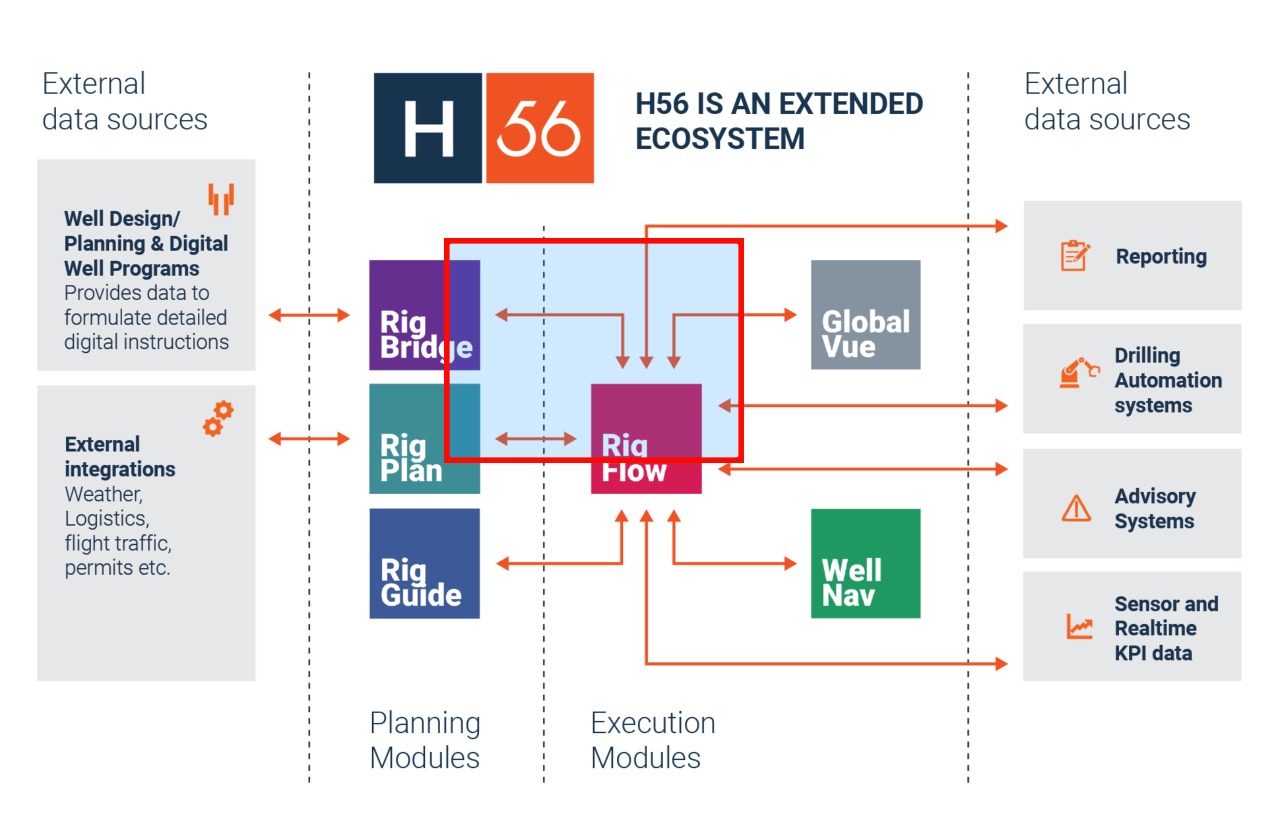

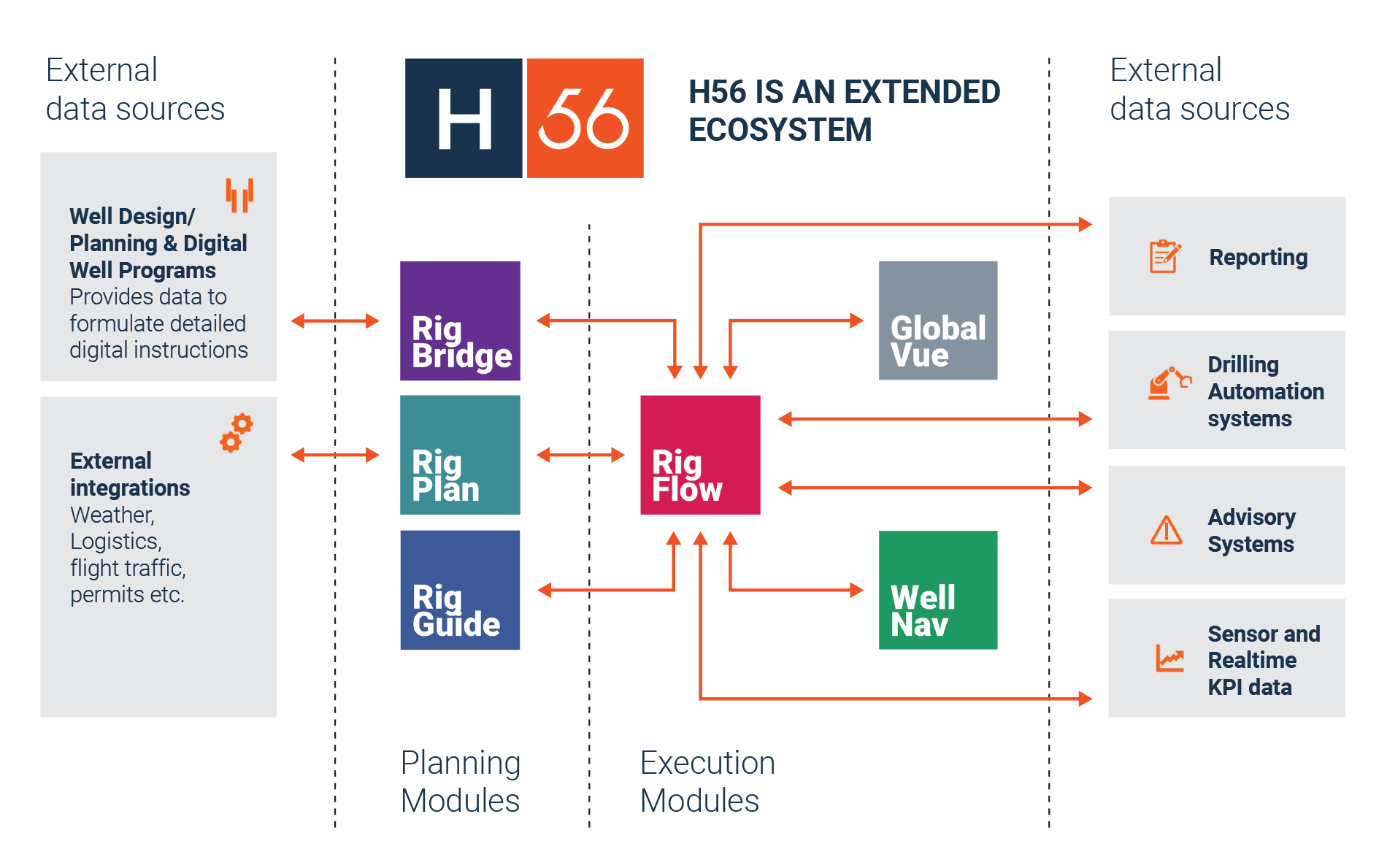

Which modules does the H56 contain?

H56 is divided into two core areas where the goal is Improved Performance, Safer Rig Operations and Increased Operational Focus. Click on the various modules to read more.

H56 structures data from most external data sources that are needed

“With H56 I am always updated in realtime and ready for my job!”

H56 enables all parties in the well construction process to perform as one team with improved efficiency and transparency. This is done by standardizing and digitalizing work-flows and information between operators, drilling contractors and service companies rig personnel in offshore drilling operations.

Iren Steinnes Drilling Supervisor, Equinor

“This is easier as we now have a library of operations in the system so copy / paste and edit is significantly easier now. Excellent that as the plan is changed and published no-one can work to an old plan which is one of the best aspects of the system.”

Drilling Supervisor, Shell