Detailed instructions for the rig team

RigBridge™ is our planning solution where users can create, approve, and publish digital, standardized, and structured work instructions.

Once published, the instructions are available in RigFlow™ for the Operations team to execute and track progress in real-time.

Revisions to instructions can be made easily in RigBridge™ and once editing is complete, all RigFlow™ users are instantly updated, ensuring everyone is aligned and working from latest plan.

…

Why RigBridge™ ?

The O&G industry has historically used static-based documents e.g. Word, PDF etc to create work instructions for the Rig team. These documents can be comprehensive and vary in format, size, and content. Additionally, creating these documents manually tends to be a complex/administrative heavy process and especially problematic during distribution and revision workflows.

RigBridge™ not only digitizes the entire written work instruction in a consistent format, but also controls the associated connected work-flow processes from instruction creation to publishing for execution. Even after execution, RigBridge™ provides users with detailed as run data and learnings so improvements can be made to similar instructions for future operations.

RigBridge™ can also host Master libraries of digital work instructions allowing for standardized instructions to be available and shared easily between different teams or departments. This can relieve users of unnecessary administrative tasks whilst also streamlining how instructions are formatted across entire organisations.

Standardized formatting

Instructions are dissected into structured content and data resulting in a consistent presentation of work instructions to the rig team.

Library of content

All digital instructions are located and available in the RigBridge™ plan library making it easy to structure and template. It’s also possible to copy and reuse existing content ranging from full projects to single parameters based on the users’ specific needs.

Plan status flow

Controlled and intuitive workflow from initial planning, to post execution after action review providing a clear overview of the status of the digital instruction.

Approval flow

The current and upcoming operations are easily accessible in various locations throughout the software promoting flexibility and user preference.

Role-based checklists

Both for preparations prior to operation and during execution, offering specific work details to unique job roles.

Attachments

All relevant attachments can be uploaded and published with the instructions. Replacing or changing attachments is done in seconds and can be pushed to the rig-crew immediately.

Specific operational data

Within each work instruction, a subset of detailed operations is added that contain input fields available for use such as operational instructions, input parameters, report backs, risks and mitigations

Revisions

Full revision control, with all stakeholders regardless of location, always having access to the latest revision. RigBridge™ also provides a comprehensive revision history, where it is possible to view and compare previous versions of the work instruction.

Operational data flowback

All operational “as-run” data is sent back from RigFlow™, in real time, to RigBridge™, allowing RigBridge™ users full transparency of operations.

Smart review

Built in, digital and powerful review process, where contributors can highlight, discuss and request input at the click of a button. All reviews are structured for easy navigation and handling.

Insights

Operational insights/lessons learned flow back from RigFlow™, with all relevant metadata automatically attached, and instantly available in RigBridge™.

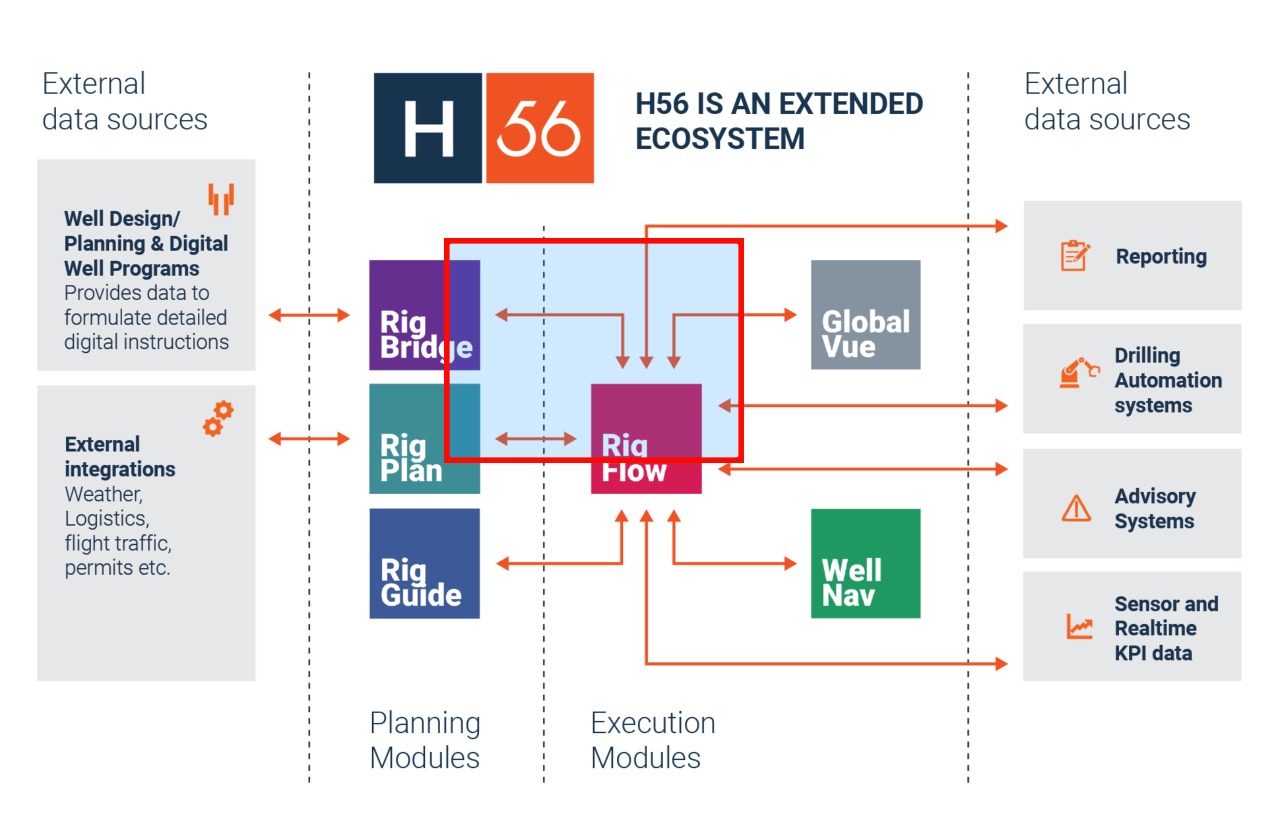

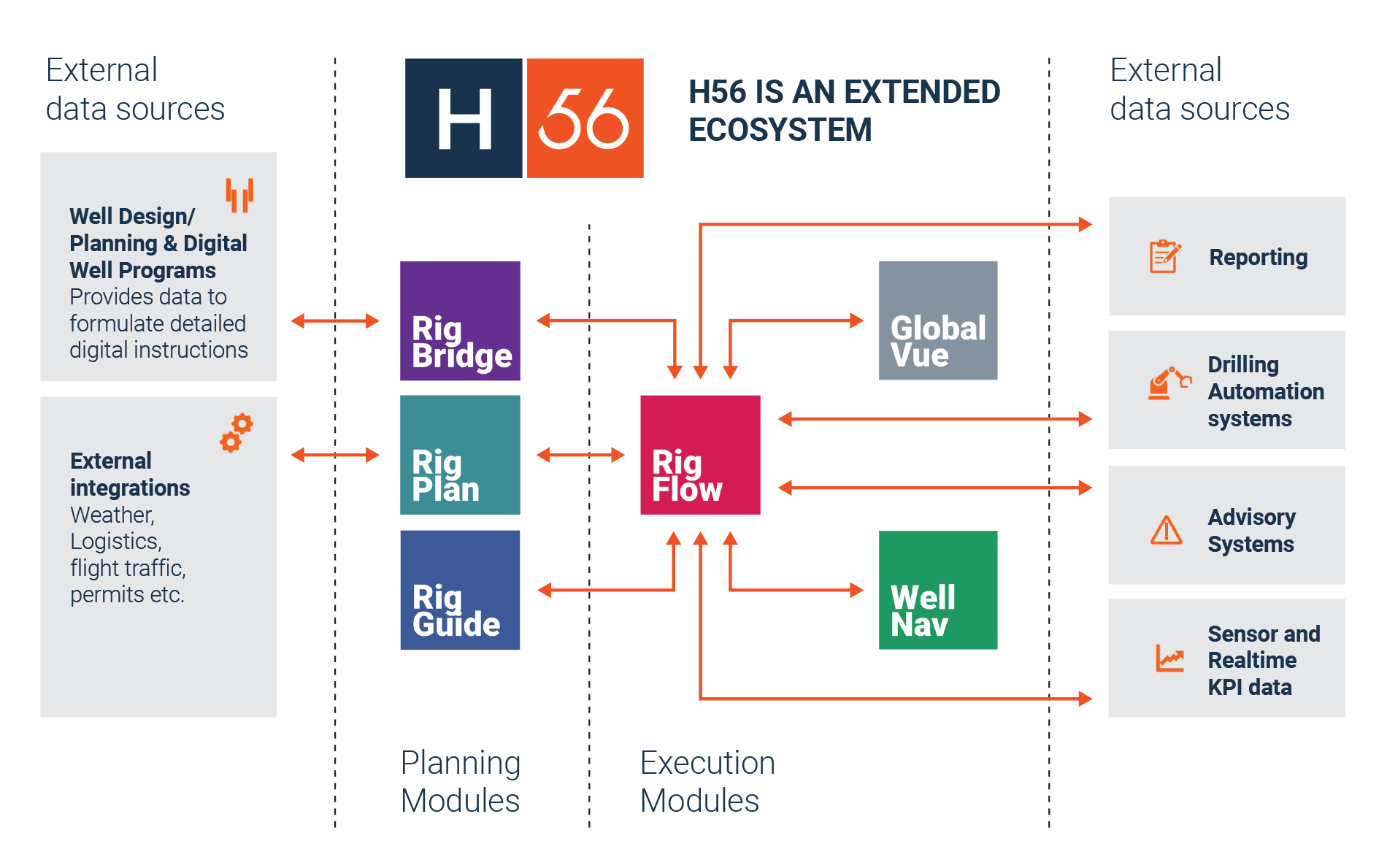

How it works as a part of H56

H56 is a complete ecosystem that gathers information from all necessary data sources needed to perform efficient well operations